Crane Finale!

We started off the last day of class with an in depth discussion of how we could safely test out the Crane, considering the extra weight and hazards a moving 5 gallon bucket of water through a shop creates. We established a Ready Call System, a Safety Boundary, Rotating Job Titles and a stack of towels.

In order for everyone to have something to do while people were operating the crane, others had the opportunity to build small projects that they had been inspired to make during their weeks spent working in the shop.

Before we could operate the Crane Luis needed to hook up the cord to the metal spool he spent so much work drilling into last week!

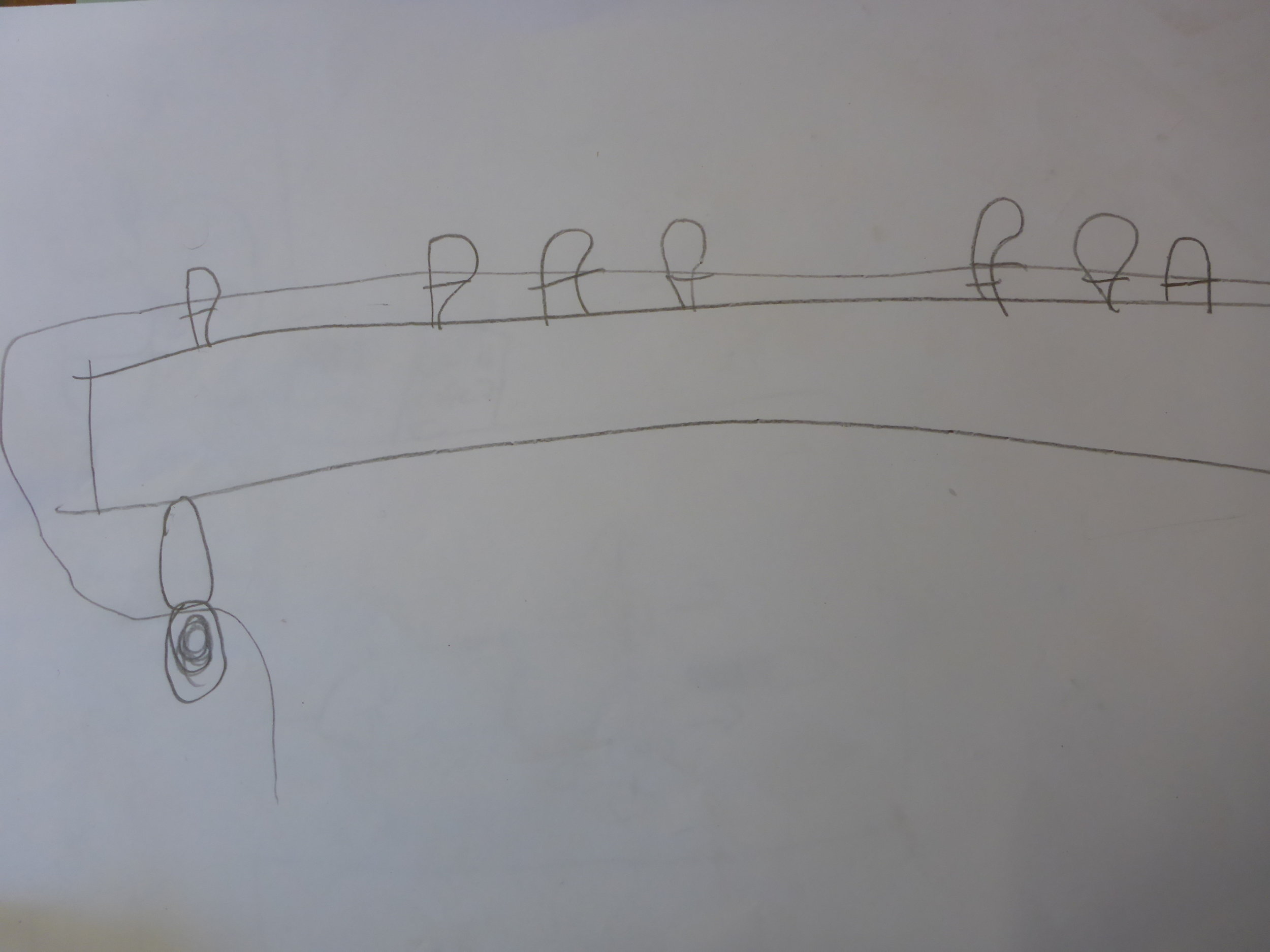

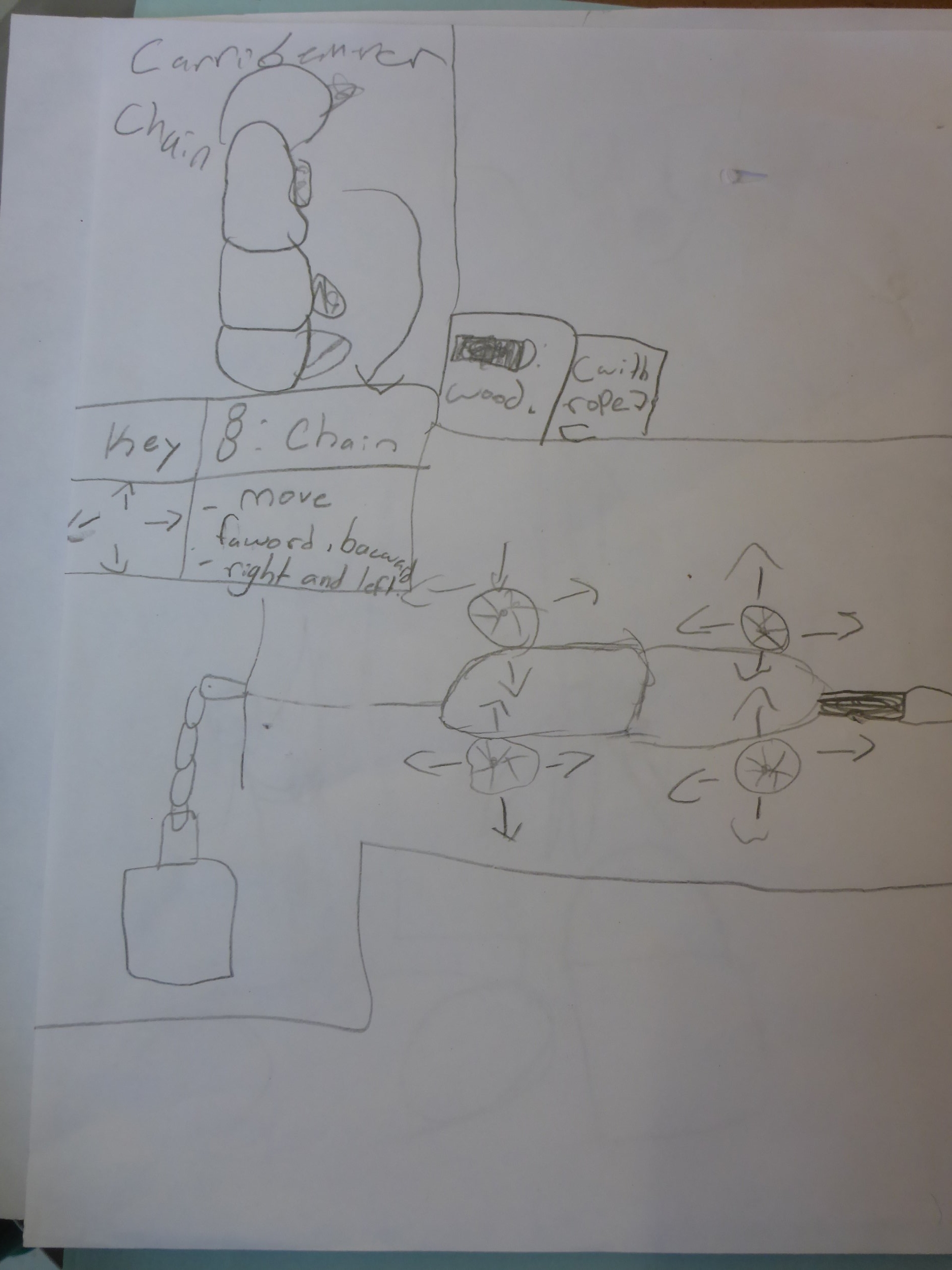

The Spool was a really great piece of this crane project for many reasons. Dmitriy and Tyler initially hatched the idea of creating a spool to run out to the pulley system and lift the hook and bucket up. They worked really hard on the pieces that would hold a reel of paracord inside the tower. A complex support system was created, so the force of the load wouldn't rip the spool off the tower! Then our paracord reel broke! The kids had to figure out how to get the cord to wrap around copper rod they had chosen. Previously the team had drilled into the metal rod to install a stopper block to keep the rod from falling out of its base and the handle. Luis decided to drill a huge hole in the rod to tie the paracord to. Of course this meant we had to take everything apart and use the drill press! The collaboration and idea building that happened during this part of the project was really magical AND the will to keep slogging through the tough/repetitive parts, brought us to this moment of a complete and functioning pulley system!

After the spool was connected we moved the arm around a bit to see what our range of motion with everything connected was - and realized we had one block that the paracord kept jumping out of. It was replaced with a smaller block that functioned much more smoothly. When were we going to get to actually use the crane, instead of undoing and redoing things?!?!?!!?

Crane Operator Ayush at the helm!

Finally with Ayush as Crane Operator, Luis as Crank Operator and Henry and I as Spotters/Navigators/Spill patrol we were ready to go!

As quietly and calmly as Ayushly possible he and Luis maneuvered the heavy hook down to the bucket handle and caught it!

The technique decided on for this first attempt was that the Crane Operator would handle the side-to-side motion only, while the Crank Operator handled the up-and-down motion.

Luis cranked and cranked and cranked and cranked the paracord through the pulley system. Ayush held on tight. We heard a crack and everyone stopped and looked. We didn't see anything. Luis cranked and cranked some more until we heard another crack! This time We saw that the arm of the crane was being pulled down towards the bucket and some plywood was getting smooshed!

We decided: "No Big Deal" and kept cranking. Soon the bucket was ever so slightly lifted off of the deck and Ayush, full of excitement, was trying to move it so carefully over to the container it needed to go in. He also had to be strong and heavy to lift the lever arm up enough to allow it to move sideways - an issue no one had foreseen in the different designing and testing phases!

The bucket made its way over to the container until it was hovering right over it! Ayush and Luis worked together to very carefully lower it inside. They had done it!!

We decided to do another run of taking the bucket out of the container and placing it on the deck. For some reason this time we had more difficulty with the stability of our swiveling fulcrum tipping over and preventing much lever action or swivel action from happening.

Through the window we can see there is too much free play which causes the base to tip over when under a lot of load :(

Luis and Ayush spent a lot of time trying different lifting techniques with the Crank and the Arm, but before we ran out of time we hadn't found a solution with just a change of human operation.

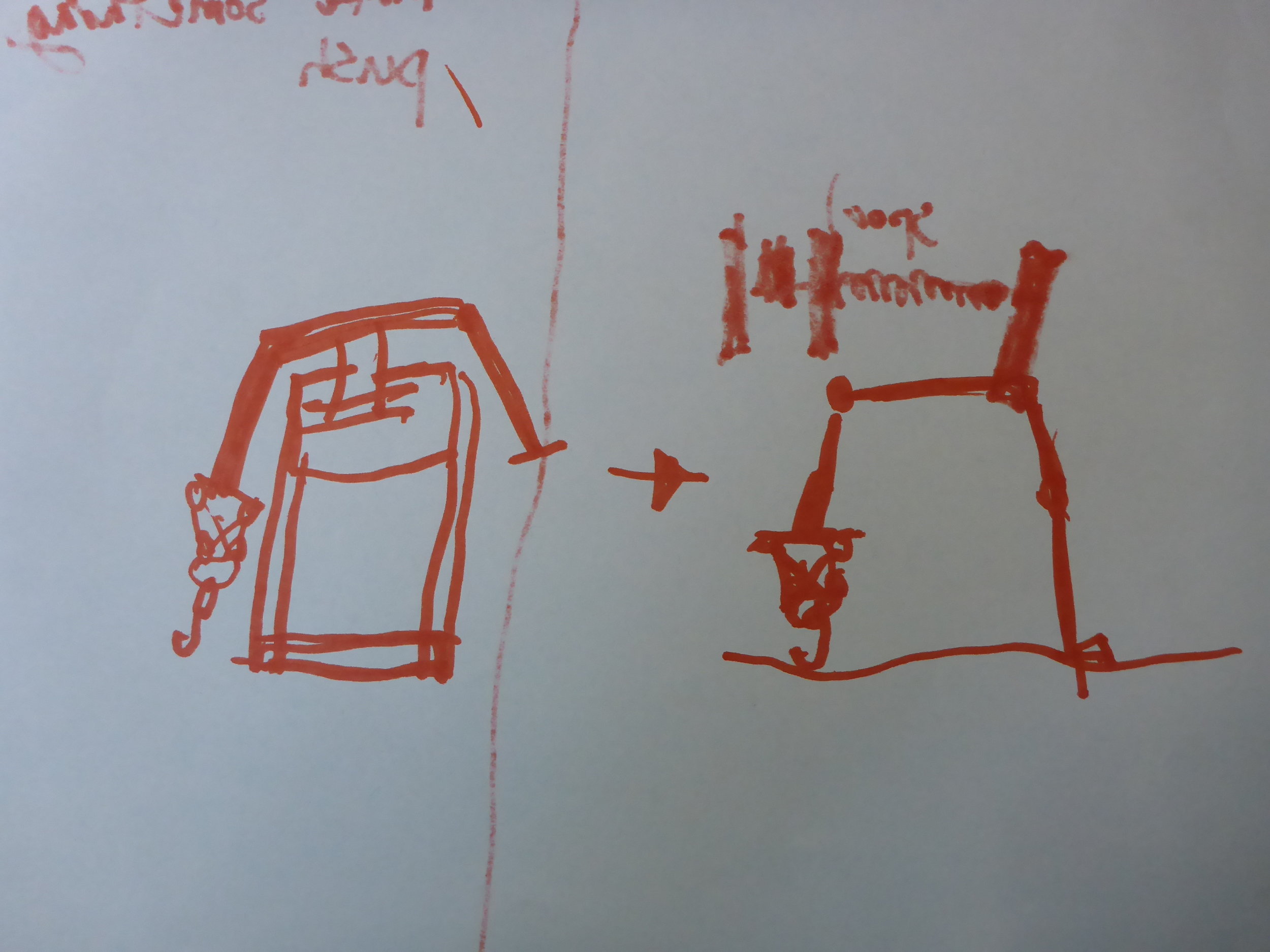

At our last closing circle of the day, the whole team discussed what kinds of solutions we could try if we had just one more day and there were some really great and diverse ideas! Adding more casters to fill up free space, adding a flat brace on top so the arm couldn't tip over, and giving the lever arm a counter weight to keep it from being pulled down by the bucket.

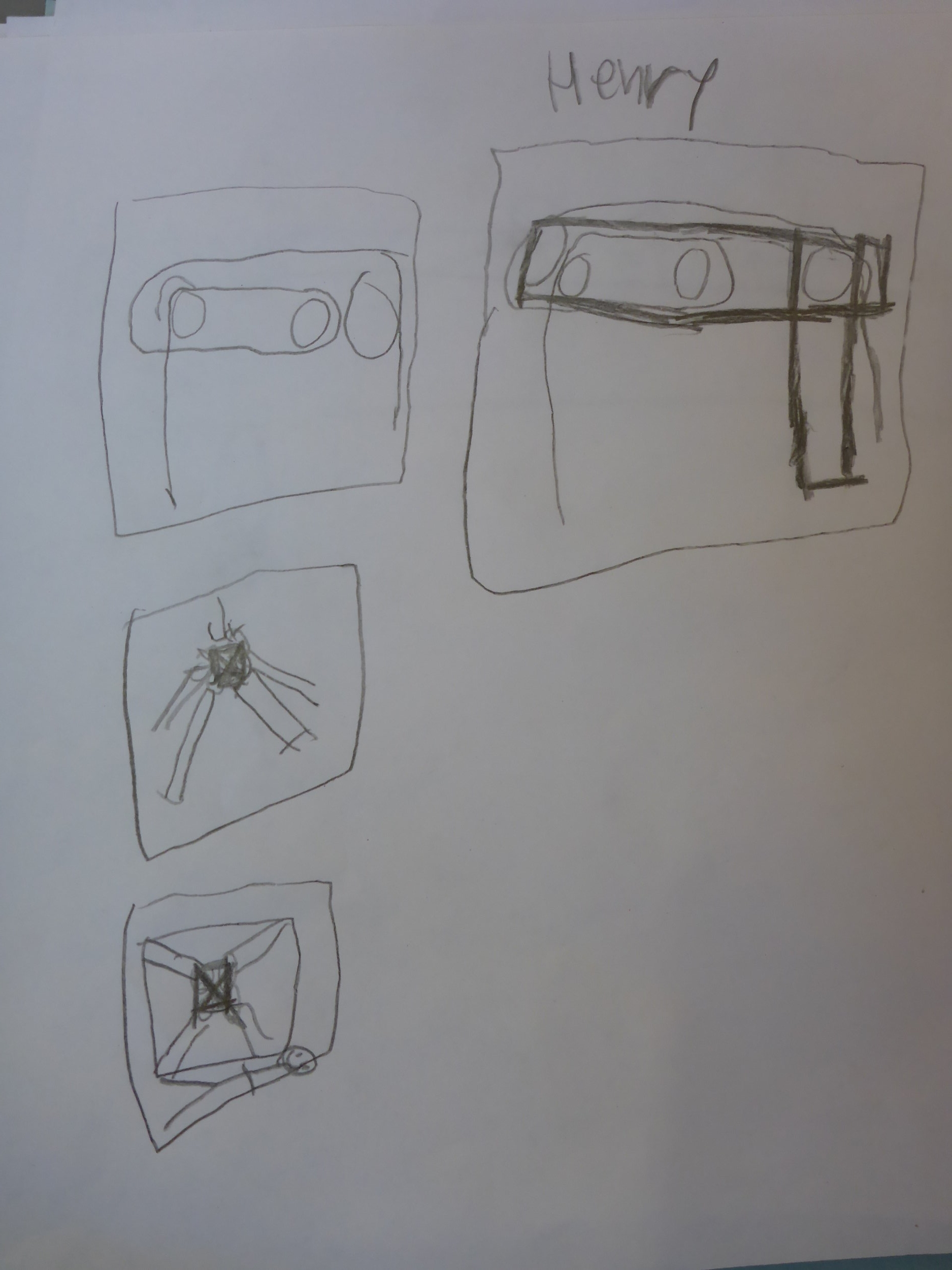

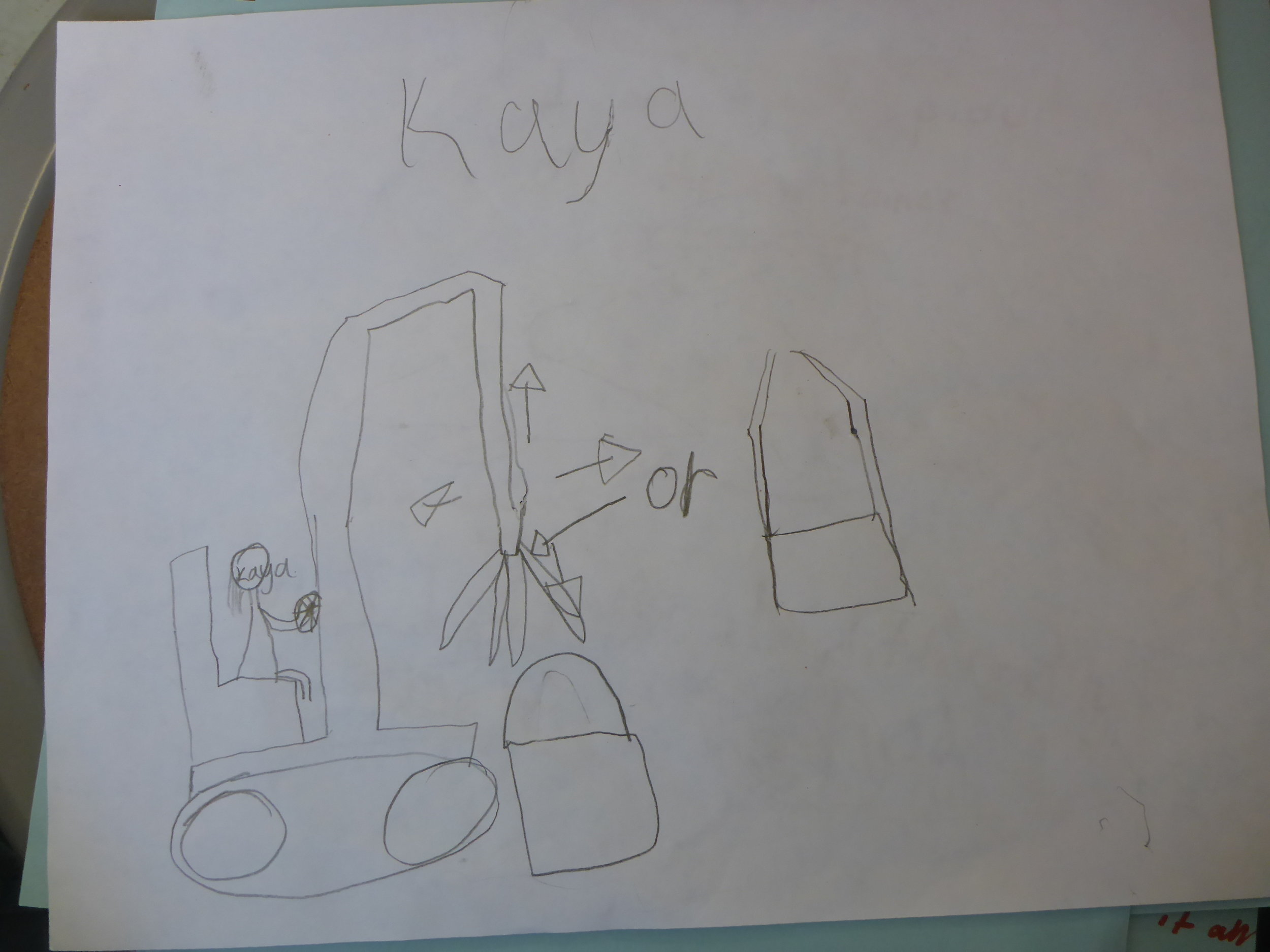

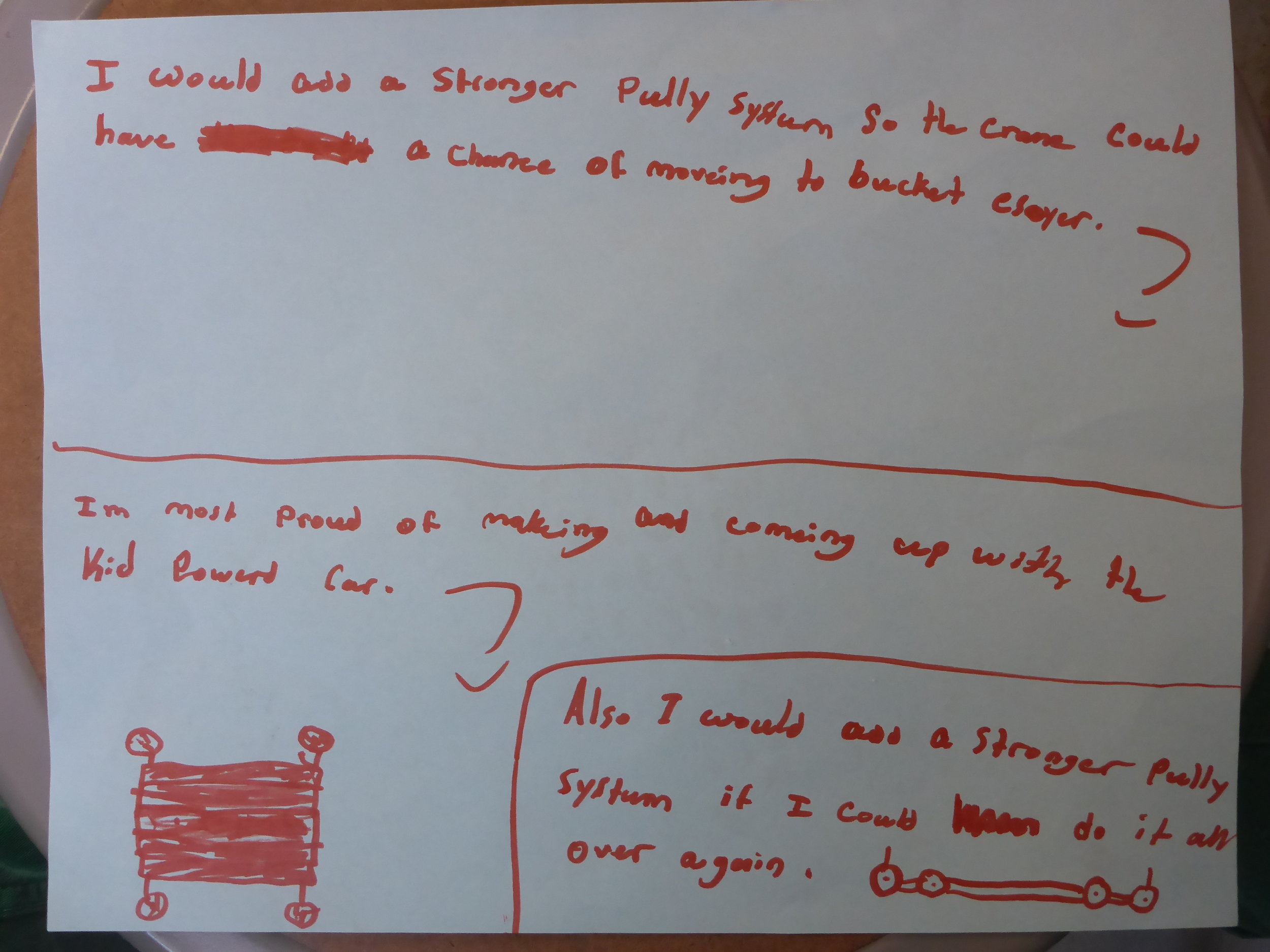

Looking at the drawings and ideas that developed from Design all the way to Reflection can show us what we are capable of, what we value most, and what we learned!

Overall this was a challenging project for the kids and the collaborators. We managed to figure out a good portion of the mechanics and we also took some time to add playful things like steering wheels, doors and artwork!